Hydraulic Machine Research Department

Activity

The Research Department of U.C.M. Resita SA, is the only one in the country in this field, it provides completely the research on hydraulic machines models, their hydro-mechanical design, as well as the research and manufacture of control equipment, and the adjustment of hydropower units, standard hydropower units and micro hydropower units connected to the National Power System (S.E.N.) or on individual network.

Within the Research Design Department we operate a lab of hydrodynamics and model design, a lab for model testing of hydraulic machines and a lab for industrial measurements and PIF (putting into operation).

The design in the field of hydraulic machines, mainly directed in the development of hydraulic models, was extended from the beginning also on improvement of some design solutions, decreasing of metal consumption by studying the stress field using the finite element method, respectively by assimilation of some parts and procedures resulted from research activities in the workshop for models and prototypes.

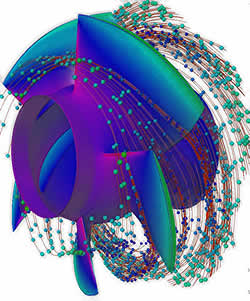

The working method is to assimilate modern calculation methods, which cannot be approached without the help of digital computer. Some of these methods are hydrodynamics of the profile networks and the method of the finite element in the studying the hydrodynamic modeling of hydraulic turbines by means of model programs. At present the activity in the field of hydropower manufacture intends, beside continuous development of high power-cavitational performant models, also to diversify the typo-dimensions, covering the power/ heads field best possible required by the arrangement, upgrading and refurbishment needs, and to develop the operational and stress calculation methods.

The main activity of the research department consists of:

- Model research and design for hydraulic turbines type: Kaplan, Kaplan bulb, Francis, Pelton, respectively pump-turbine models type: Kaplan bulb, Francis. Also a special place in the activity of the research department is taken by the development of mini-turbine, micro-turbine and nano-turbine prototypes, impact pumps (hydraulic ram) intended for irrigation in agriculture, the development of water ejectors, respectively axial and radial slide bearings for hydraulic turbines and electric machines.

- CAD and hydrodynamic modeling of assemblies and items comprised within the hydraulic machines, respectively own design in the development of programs for hydrodynamic calculation of elements for hydraulic machines. This involves the analysis by finite element, of the static stress conditions that occur in parts at different stresses, modeling and optimization of blade profile (BladeGen) and also the finite element analysis of hydrodynamic flow, optimizing the hydraulic circuit of hydraulic machines using specialized flow programs (AEA Tascflow).

- Power and cavitational measurements of hydraulic machine models on own test stands to determine the universal diagrams of models, and of force and torque characteristics for design method validation. This activity is permanent and leads to building the own model assets and to improve the existing ones, as well as part of studies and research contracts to increase performance of hydraulic machines in service.

- Warranty measurements intended to certify the performance of our own hydraulic turbine models.

- Testing of new design concepts for valves with circular section.

Achievements

The hydraulic impact pump. Many agricultural fields are located at large distances from any power sources, in this case the classical irrigation systems are of no use. As the impact pump doesn't need power supply, it is the cheapest way to create an irrigation possibility in the areas where water sources are very poor, such as: water streams, small rivers, water channels, etc. The hydraulic impact pump is a machine intended to rise the water by means of hydraulic impact. It uses the water hydraulic energy in order to pump it and it is cheaper than the classical ones. With an intake discharge of Q = 20 l/sec, an outlet discharge can be obtained of q = 3 l/sec and the pumping height can reach up to 4.5 m at a level difference of 1 m. The installing method is simple requiring minimum investments for arrangement.

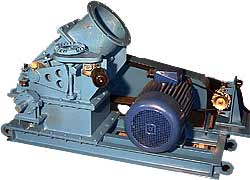

The Banky type micro hydropower unit is intended to fit the micro hydropower stations for power supply both in the national system and on individual network. In case of operation on isolated network it can supply power for driving of electric motors or it can provide electric lighting and heating. This type of hydropower unit is delivered together with induction electric generator and the automation panel, adapted depending on the station parameters and the operation condition.

Main technical characteristics:

- Nominal diameter of runner Dn = 250 mm

- Head range H = 4...40 m

- Discharge range Q = 0.075...0.240 mc/s

- Range of power supply P = 1.9...50 kW

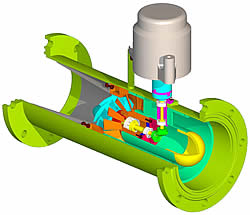

Hydraulic micro turbine with double control, type KOT-600. This micro turbine, having a hollow shape line, is intended to fit the micro power stations and it discharges electric power into individual network or in the National System, having the capacity to capitalize the low head hydropower potential in isolated areas. The micro turbine can operate in a large range of heads and discharges and can provide power supply with voltage and frequency acc. to the norms and standards. The runner adjustment is based on modern conception, applied for the first time, which allows decreasing of cost and increasing of performance.

Technical characteristics:

- characteristic diameter of runner D1 = 600 mm

- maximum head Hmax = 12.00 m

- designed head Hc = 7.00 m

- minimum head Hmin = 3.7 m

- maximum absorbed discharges:

- at minimum head Qmax.abs. = 2 m3/s

- at designed and maximum head Qmax.abs. = 2.5 m3/s

- maximum power at turbine coupling Pmax. = 265 kW

- maximum intake load Hsmax. = -4.5 m

Axial-tubular micro hydropower unit. It was designed and manufactured in order to fit an isolated micro hydropower station. It is intended for some stations where the discharge Qc is 112...130 l/s, and the head H c is within 3...3.5 m. The resulted power is of 4 kV. It is designed in a solid construction with no pollutant conditions, its housing being performed from a pipe with Dn = 350 mm, the monoblock runner of axial type and the conical wicket gate of fixed type. The moment is sent from the turbine shaft to the generator by a conical gear at 90 degrees. Together with the automation that fits the micro power unit to the requirements of the users, it is ideal for the supply of a cottage, located far away from the power network.

Micro hydropower units of wide use (MLU). This type of units are intended for use in the head range of 16...35 m and discharges within 145...370 l/s and they can operate individual or connected to the national power system. They are designed in the power range between 4 and 80 kW, the supplied power depending on the available head and discharge. The power unit is fitted with an automation and control panel, having also a protection device at runaway speed both for operation in individual system and for operation connected to the national power system. When operating in individual system, they can be used to provide lighting, power supply of electric motors, etc.

Pelton micro turbine.This type of hydropower unit consists of a solid design, being able to operate individually or connected to the national power system. This type of units are intended for use in the head range of 40...125 m and discharges Q = 13...126 l/s and they can supply power between 5 and 140 kW. The Pelton micro turbine is characterized by a high performance, relatively constant at significant variation of the discharge. The location of the housing cover provides easy access for runner/nozzles assembly-dismantling. This is an ecological, non-pollutant conception.

Endowment of the lab within the research development department

U.C.M. Resita, the research department is endowed with a modern research lab for hydraulic machines which provides researches for:

- models of hydraulic turbines type Bulb, Kaplan, Deriaz, Francis, Pelton

- models of pump-turbines and turbine-pumps type Bulb and Francis

- micro turbines with output within 5 and 1200 kW

- pumps for pumping stations

- valves

- speed governors for hydraulic turbines

- static excitation systems for hydro generators

- electric equipment for micro turbines

- resistance tests for the subassemblies of hydraulic machines

- transient state tests of hydropower units

- monitoring of turbines and micro turbines in service

Material basis of the lab consists of: test stands for turbine and pump-turbine models, high accuracy equipment and devices for measuring and control.

For any other details concerning these test stands download this document, in pdf form.

---------------------

---------------------