The department for the design of hydro-mechanical equipment

The department for the design of hydro-mechanical equipment

Activity

The activity of the design department for the hydro-mechanical equipment (SPIH) is structured on the design of valve units and pumping stations for HPPs and also on the design of auxiliary equipment for HPPs.

The valves, used as locking elements, located at the inlet to the spiral case of the hydropower turbines (inlet valves), or at the inlet to the penstock (water tower valves), are custom designed. The type of inlet valves and water tower valves designed in this department are butterfly valves- biplane chamfered and lens shape disk including auxiliary units; and spherical valves including auxiliary units. It is important to mention that the same department designs also butterfly valves for nuclear power plants - Nuclear Power Plant Cernavoda.

Within the class of control and locking valves, located on the bottom discharge and/ or sand trap pipes, we can state conical valves, lemon valves, hollow jet valves and cut-off jet valves. We are the sole manufacturers of hollow jet and cut-off jet valves in Romania and Europe.

The safety valves located in front of discharge valves, designed within the department, are cut-off slide valves, including auxiliary units and follower-ring valves.

For by-pass units of the butterfly and spherical valves stated above, the department designs hollow jet valves and needle valves.

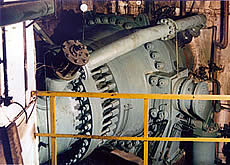

The auxiliary units for the hydropower units designed in this department, comprise pressure oil groups (GUP), cooling water units for the hydropower units and HPP, ejectors and units for operation in synchronous compensator of hydraulic turbines.

The departments provides complex documents of calculation summary type, test procedures, material specification, house test instructions, assembly instructions, operation and maintenance instructions, studies for fitting, upgrading and rehabilitation of spherical and butterfly valves, GUP, cooling and lubricating equipment.

Experts from this department provide the technical assistance for assembly and putting into operation (PIF).

For all a.m. objectives the department draw-up technical offers.

Main objectives

Gezende Dam and HPP - Turkey. Design of butterfly valve for water tower with biplane disk and hydraulic driving system. This is the valve with the largest inlet diameter designed by U.C.M. Resita. Technical characteristics: inlet diameter Dn = 5000 mm and designed head H = 100 w.c.m. This was a national premiere at that time. It is in operation with good results for over 10 years. It was a success in design.

HPP Râul Mare Retezat - Romania. The largest spherical valve with the most complex hydraulic drive designed and manufactured by U.C.M. Resita. Technical characteristics: inlet diameter Dn = 2200 mm and designed head H = 770 w.c.m. This was a national premiere at that time, performed completely by U.C.M. Resita. It is in operation with good results for about 18 years, being a success in design and manufacture. The experience achieved allowed us to approach other similar projects.

Nuclear Power Plant Cernavoda, Romania. Butterfly valve with electro-mechanical drive, located in a pumping station. The design of the valve is lens shape disk with double sealing. The intake diameter of the valve is Dn = 2800 mm and the design head is H = 40 w.c.m. This was a national premiere at that time for the nuclear power plant Cernavoda. It was manufactured by U.C.M. Resita. It is in operation with good results for about 10 years, being a success in design and manufacture.

Otaky HPP, Japan. It is the first butterfly valve with biplane disk and electro-mechanical drive, exported in Japan. Technical characteristics: inlet diameter Dn = 2300 mm and designed head H = 81.5 w.c.m. This was designed and performed completely by U.C.M. Resita. The year of putting into operation is 2002.

Wonorejo Multipurpose Dam Project - Indonesia. Slide cut-off valve, inlet diameter Dn = 1600 mm and designed head H = 83.439 w.c.m. This was a national premiere at that time, performed by U.C.M. Resita, being a success in design and manufacture. The year of putting into operation is 2001.

Wonorejo Multipurpose Dam Project - Indonesia. Hollow jet valve with hydraulic drive, inlet diameter Dn = 1600 mm and designed head H = 83.439 w.c.m. This was a national and European premiere at that time, performed by U.C.M. Resita, being a success in design and manufacture. The year of putting into operation is 2001.It was the start point for the design of other jet valves. The experience achieved allowed us to approach other similar projects.

Discharge Facilities for Bao-Shan No.2 Dam Project - Taiwan (Republic of China). First follower-ring valve with electro-mechanical drive designed and performed by U.C.M. Resita. Technical characteristics: inlet diameter Dn = 1500 mm and designed head H = 48.4 w.c.m. . This was a national premiere at that time. It was the start point for the design of other follower-ring valves. The experience achieved allowed us to approach other similar projects, considering that the year of manufacture is 2004.

Discharge Facilities for Bao-Shan No.2 Dam Project - Taiwan (Republic of China). First cut-off jet valve with electro-mechanical drive designed and performed by U.C.M. Resita. Technical characteristics: inlet diameter Dn = 600 mm and designed head H = 48.4 w.c.m. . This was a national premiere at that time. It was the start point for the design of other cut-off jet valves. The experience achieved allowed us to approach other similar projects, considering that the year of manufacture is 2004.

HPP Iron Gates II- Gogosu- Romania. Pressure oil group, symbol GUP 16-40. Technical characteristics:

- rated pressure 40 bar

- nominal capacity of the accumulator 16 m3

- main pump discharge 13.9 l/sec

- auxiliary pump discharge 6.2 l/sec

The oil pressure group is designed to correspond for the supply of pressure oil in the HPP Iron Gates II. Ten pieces of oil pressure groups were manufactured in U.C.M. Resita and they had good behavior in operation for 15-20 years. The technical concepts used in the design and manufacture of these groups have been further used for other oil pressure groups.

HPP Râul Alb Romania. Pressure oil group, symbol GUP 1-40. Technical characteristics:

- rated pressure 40 bar

- nominal capacity of the accumulator 1 m3

- pump discharge 110 l/sec

- air compressor discharge 0.2 m3/min

The oil pressure group was designed based on the achieved experience. The group is solid designed consisting of pumps, transducer for pressure, level and temperature measurements. Special fittings and ball valves were used in order to provide a simple and safe operational diagram. All pipes, flanges and locking fittings are made of stainless steel. The group is provided with its own air compressor. The GUP from the HPP includes also an oil filtering station. The entire oil pressure group is in process of manufacture in U.C.M. Resita and represents a national premiere at this moment.

HPP Iron Gates II - Gogosu - Romania. Distilled water-cooling system of the hydro generator. Technical characteristics: pump discharge = 39 m3/h; pumping height = 70 w.c.m. The distilled water-cooling system of the runner and stay ring for the hydro generators of HPP Iron Gates II Gogosu and CSY was a national premiere. The system provides a safe operation, being in service for about 20 years. They have been designed and manufactured by U.C.M. Resita to be fitted on 10 hydropower units. The system operates in closed circuit and it is provided with a complex and safe automation.

New products

First butterfly valve for HPP Otaky, in Japan. The valve is with biplane disk, calculated by means of finite element method. Driving is performed electro-mechanically, with AUMA - Germany mechanism. Technical characteristics: nominal diameter Dn = 2300 mm and designed head H = 81.5 w.c.m. This was designed and performed completely by U.C.M. Resita. The year of putting into operation is 2002.

First hollow jet valve, for Wonorejo Multipurpose Dam Project - Indonesia. It is a control valve located on the bottom-discharge of Wonorejo Dam. It has hydraulic drive, inlet diameter Dn = 1600 mm and designed head H = 83.439 w.c.m. It is assembled at downstream of the pipe, as final control and locking element. The discharge coefficient of the valve is higher than 0.8. The sealing is of metal/metal type, the shutter moving in opposite direction to the water flow, in order to perform the control and locking function of the valve. The water profile at valve outlet is cylindrical core-less shape, meaning the shape of hollow jet. This was a national and European premiere, performed by U.C.M. Resita, being a success in design and manufacture. The year of putting into operation is 2001. It was the start point for the design of other hollow jet valves at HPP Bao-Shan - Taiwan and Taham Dam - Iran, valves with electro mechanic drive.

First follower-ring valve for Taiwan (Republic of China). It is a safety valve that will be located in the HPP Bao-Shan - Discharge Facilities Project. It has an electro-mechanical driving mechanism of Limitorque Nipon Gear type and it was designed and performed by U.C.M. Resita. Technical characteristics: inlet diameter Dn = 1500 mm and designed head H = 48.4 w.c.m. The discharge coefficient of the valve is of about 1. The sealing is of metal/ metal type, and the sealing plate is follower-ring shape, which gives the name of this valve. It is a national premiere and it is the start point for the design of other follower-ring valves such as the follower-ring valve Dn 600. The year of manufacture is 2004.

First cut-off jet valve for Bao-Shan - Taiwan (Republic of China) It is a control valve with electro-mechanical drive, with inlet diameter Dn = 600 mm and designed head H = 48.4 w.c.m. It is assembled at downstream of the pipe, as final control and locking element. The discharge coefficient of the valve is higher than 0.8.The body of the valve is not subjected to water pressure. The sealing is of metal/metal type, consisting of a movable sealing ring actuating the shutter of the valve. The shutter moves perpendicularly to the direction of the water flow. For maximum opened position of the valve the water profile at the valve outlet has the shape of a full cylinder. The valve is driven by means of a Limitorque Nipon Gear mechanism. This is a national and European premiere, manufactured in U.C.M. Resita. It is the start point for the design of other cut-off jet valves. The year of manufacture is 2004.